Popcorn Packaging Machine

Pain Points & Solutions

Inefficiency & Slow Production Speeds

Our packaging machines can achieve up to 100+ packages per minute, dramatically increasing your output and reducing the need for manual labor.

High Labor Costs

By automating your packaging line, you can reduce the need for multiple workers, lowering overall labor costs by up to 60%

Packaging Inconsistencies & Errors

Our Solid Packaging Solution use advanced sensors to ensure precise fill levels and consistent seals, minimizing product waste and maximizing quality control.

Packaging Material Waste

Customize Packaging Machines are optimized to reduce material usage by up to 20%, cutting costs and contributing to your sustainability goals

Popcorn Packaging Machine

Are you looking to increase production efficiency, improve packaging consistency, and reduce costs? Our Popcorn Packing Machines are the perfect solution for the food industry. With advanced automation, precise filling technology, and customizable packaging options, our machines ensure your candy products are packed securely, efficiently, and with the utmost care.

Supports a variety of bag types such as three-side sealed flat bags, stand-up bags, zipper bags, self-supporting bags, etc.

For businesses in the confectionery, nutraceutical, or pharmaceutical industries, investing in the right popcorn packaging machine can significantly enhance productivity, consistency, and product quality while reducing labor costs and waste.

Premade Pouch Packing Machine

Premade pouch doypack machine generally requires customers to provide prefabricated bags by themselves, which can be suitable for zipper bags, stand up pouches, etc.,

Features:

-

- Specialty packaging with zippers or stand-up functionality.

- High-speed, precise filling, and sealing.

- Customizable features like zip-locks and spouts.

- Easy to operate with a user-friendly interface.

- Especially suitable for products with high requirements on packaging aesthetics

- Optional functions: nitrogen filling for freshness preservation, labeling, leak detection, etc.

VFFS Packaging Machine

VFFS machines are a common and adaptable equipment for packaging popcorn. In a continuous vertical operation, they make bags out of a roll of film, stuff them with popcorn, and seal them,

Features:

-

- Packaging speeds of 10-60 packs per minute

- Bag size flexibility, usually 80-350mm length and 80-250mm width

- Weight ranges from 10-1000 grams

- Forms pouches from flat film rolls(3 side seal or pillow bag,stand-up pouch,gusseted bags .)

- Flexible film handling for different applications.

- Precise filling for consistent product packaging.

- Control parameters (bag length, temperature, speed, etc.) through PLC and touch screen, support fast switching of packaging specifications

Frequently Asked Questions

Most frequent questions and answers

How do I choose the right popcorn packaging machine for my business?

Consider factors such as your production volume, the type of popcorn (plain, flavored, microwave), preferred packaging material and style, available space, budget, and the level of after-sales support and maintenance required

What is the typical speed and capacity of a popcorn packaging machine?

Packaging speeds generally range from 10 to 80 bags per minute, depending on the machine type and configuration. Multi-lane machines can achieve even higher outputs for large-scale operations.

Can these machines handle different types of popcorn and packaging styles?

Yes, our most modern machines can package various types of popcorn, including plain, flavored, caramel, and microwave popcorn, and can produce pillow bags, gusseted bags, stand-up pouches, and more

How long is the machine warranty? If the spare parts are broken, can you provide them?

Our packaging machine comes with a 1-year warranty, with lifetime customer support and maintenance services available.

We will give you 2 extra sets of accessories to ensure that the factory can perform repairs without stopping the machine.

How to ensure the machine quality as you mentioned?

Quality is built in, not tested. Our machine has been CE-certified. We’ll provide detailed videos and photos for your review until you’re fully satisfied. Additionally, you or a professional inspection company are welcome to visit our factory before delivery.

How about your after sales service?

All of our machines come with a user manual, and we provide detailed videos covering machine installation, commissioning, and troubleshooting for common issues.Engineers are also avaliable to serve oversea.

Why Customer Choose us

Facts

Thanks to years of hands-on experience working directly in industries, our sector managers have a deep understanding of how their sector works.

Mission

We ensure that every minute detail is looked into while manufacturing even the smallest product. Our focus is 100% on customer needs and satisfaction.

Industry experience

Here you will get a personalised engineering service, professional guidance, up-to-date information on the latest knowledge and the possibility to improve your designs.

Cool Facts

Testimonials

How It Works

Choose your packaging material

- Select from various options such as vacuum bags, pouches, or other container.

Set up your popcorn product

- Place popcorn on the conveyor belt and configure the machine to the desired weight and size.

Watch the magic happen

- The machine automatically fills, seals, and labels the packages, ready for shipping.

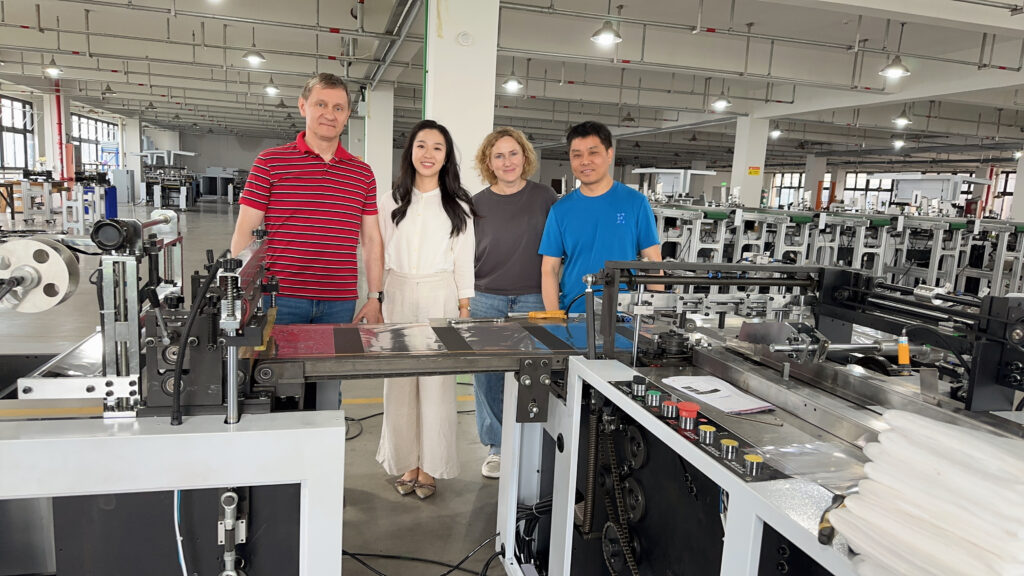

Pouch Packaging Machine Workshop

Horizontal Form Fill Seal Machine Workshp

Vertical Form Fill Seal Machine Workshop

Ready to Upgrade Your Popcorn Packaging?

Get your popcorn packing process running at full capacity with our cutting-edge technology.

Email:[email protected]

Tel:+8613868827095