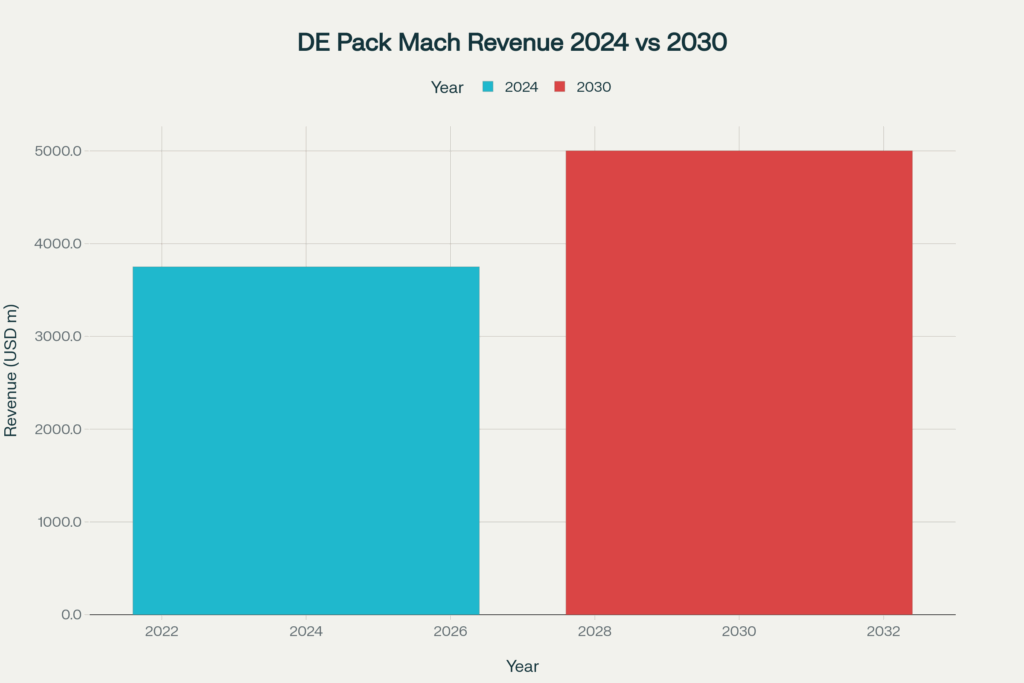

In today’s fast – paced manufacturing landscape, packaging machinery isn’t just an operational necessity—it’s a strategic asset driving efficiency, quality, and growth. Germany, home to one of world’s most advanced mechanical engineering sectors, has a robust packaging machinery industry. It saw revenue of USD 3,750.7 million in 2024. By 2030, it’s projected to hit USD 5,001.8 million.

Market Overview and Growth Drivers

Germany’s packaging machinery sector is a cornerstone of its mechanical engineering prowess. It accounts for nearly half of European market sales. Strong export demand fuels it.

Market Size and Forecast

- 2024 Revenue: USD 3,750.7 million

- 2030 Forecast: USD 5,001.8 million

- CAGR (2025–2030): 5%

Key Growth Drivers

- Export Leadership: Germany exports over 48% of its machines to other European nations. 19% go to Asia, notably China at €495 million in 2022 (up 16%).

- Regulatory Clarity: EU packaging regulations adopted on April 2024 create standardized conditions. They bolster investor confidence.

- Industry 4.0 Integration: Adoption of AI, IoT, and robotics rises for smarter, more flexible packaging lines.

- Sustainability Trends: Demand for recyclable and minimal – material packaging drives innovation in eco – friendly machinery.

Advantages of Modern Packaging Machinery

Enhanced Efficiency and Throughput

Automation lets German manufacturers achieve high – speed, continuous production with minimal downtime. It meets tight delivery schedules and large – volume orders.

Consistent Quality and Accuracy

Precision dosing, sealing, and labeling cut product variability and waste. They ensure every package meets stringent quality standards—a crucial factor for food, pharmaceutical, and cosmetics sectors.

Cost Savings over Time

Although initially capital – intensive, advanced machinery lowers labour costs. It minimizes material wastage and reduces error – related rework. It delivers significant ROI across the machine’s lifecycle.

Safety and Compliance

Automated processes limit worker exposure to hazardous operations. They guarantee sterile, tamper – evident packaging—vital for pharmaceuticals and sensitive goods.

Industry Applications

Food & Beverage

German food – processing and packaging machinery hit a record production value of €16.5 billion in 2023. Packaging equipment contributed nearly €8 billion—a 10% increase year – on – year.

Pharmaceuticals

With strict hygiene and dosage requirements, pharmaceutical companies rely on precision filling, induction sealing, and automated inspection. They ensure safety and traceability.

Cosmetics & Personal Care

Aesthetic packaging and exact volumetric filling are critical for cosmetics. German machinery offers customizable solutions for premium brand presentation.

Other Sectors

- Chemicals: Robust, corrosion – resistant machines handle industrial chemicals safely.

- Agriculture: Auger and volumetric filling systems work for seeds, grains, and animal feed.

- Logistics & E – Commerce: High – speed case packers, palletizers, and stretch wrappers handle large – scale order fulfilment.

Types of Packaging Machinery

Germany’s leading OEMs and Lintyco Pack supply a full spectrum of machines

| Machine Type | Function |

|---|---|

| Liquid Filling (Gravity, Piston, Vacuum) | Handles thin to viscous liquids like water, sauces, and wines |

| Powder Filling (Auger) | Accurate dosing of flour, cocoa, and protein powders |

| Solid Filling (Multi – Head Weighers) | Packs nuts, coffee beans, pet food |

| Sealing (Heat, Induction) | Creates airtight seals for freshness and tamper evidence |

| Capping & Labeling | Applies caps and labels with precise torque and vision – controlled alignment |

| Form – Fill – Seal (VFFS, HFFS) | Vertical and horizontal pouch forming, filling, and sealing |

| End – of – Line (Case Packing, Palletizing) | Automates carton erecting, sealing, and pallet stacking for distribution |

Cost Considerations in Germany

Price Range by Automation Level

- Entry – Level (Semi – automatic): €20,000–€60,000. It’s ideal for SMEs with moderate throughput needs.

- Mid – Range (Automatic FFS, Labelers): €80,000–€200,000. It suits medium – scale operations.

- Fully Automated: €400,000+. It includes high – speed VFFS systems and robotic palletizers for large manufacturers.

Factors Influencing Cost

- Automation Level: Semi – vs. fully automatic systems (very high impact).

- Production Capacity: Throughput requirements drive frame size and throughput components.

- Advanced Features: Touchscreens, servo drives, and vision inspection (medium impact).

- Compliance & Certification: CE, ISO, and FDA certifications add to costs but ensure market access.

Choosing the Right Supplier

Quality & Certification

Look for ISO 9001, CE – marking, and FDA compliance. They meet international standards and facilitate export.

After – Sales Service

- Technical Support: 24/7 hotline and rapid on – site repair.

- Spare Parts Availability: Guaranteed long – term parts supply.

- Training & Maintenance: Scheduled programs maximize uptime.

Reputation & Track Record

Top German OEMs—Krones, Syntegon, KHS, IMA Group, Geiger, Lintyco and Hesser—offer proven reliability and global service networks.

Why Choose Lintyco Pack?

As a featured supplier, Lintyco Pack offers German manufacturers:

- Proven Reliability: Over 15 years of innovation, 90+ patents, and CE/ISO certifications.

- Global Expertise, Local Support: 500+ employees worldwide, including dedicated German service teams.

- Flexible Solutions: Modular designs enable rapid changeovers across multiple product formats.

- Industry 4.0-Ready: PLC-driven controls, vision inspection, and data analytics for predictive maintenance.

- Sustainability Focus: Machines engineered for energy efficiency and minimal material waste.

Conclusion

Germany’s packaging machinery industry is on track to exceed USD 5 billion by 2030, driven by export prowess, digitalization, and eco-friendly innovation. Partnering with a featured supplier like Lintyco Pack ensures access to proven, flexible, and future-ready equipment backed by local support. Whether you’re a startup seeking semi-automatic form-fill-seal solutions or an established enterprise scaling to fully automated, Industry 4.0-enabled lines, Lintyco Pack delivers the expertise and technology to propel your success.