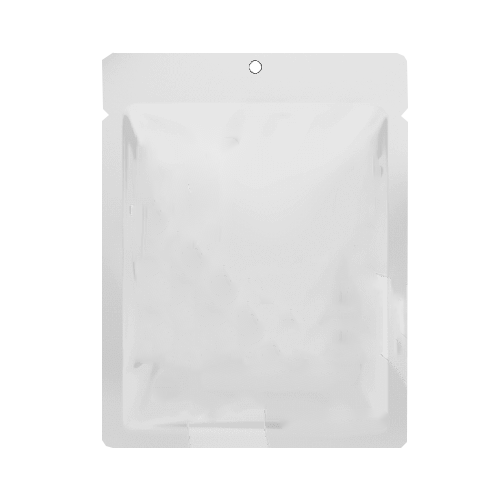

When it comes to protein powder packaging, healthy powder manufacturer search for best packaging solutions. These solutions maintain product integrity, maximize shelf appeal, and ensure consumer convenience. Among many options, 4 side seal sachets become preferred choice for brands and consumers. This is due to their durability and versatility.

What Makes 4 Side Seal Sachets Stand Out?

- Comprehensive Protection: These sachets are fully sealed on all four sides. They create an airtight and moisture – proof barrier. This is crucial for sensitive nature of protein powders.

- Uniform Shape for Consistency: Their sleek and tidy appearance makes them excellent for retail displays or e – commerce shipments. They offer professional presentation every time.

- Ideal for Single Servings: 4 side seal sachets are perfect for single – serve or sample – sized protein powders. They support growing trends on both fitness and convenience nutrition.

- Leak – Proof Security: Compared to alternatives, superior sealing provides strong defense against leaks and contamination. It reassures both retailers and consumers.

- Customizable Size and Branding: These sachets can be tailored on size and printed with eye – catching designs. This makes your brand stand out on shelves.

Why Are Brands Switching to 4 Side Seal Sachets?

Growth on fitness and wellness markets has increased demand for innovative, secure packaging. 4 side seal sachets dominate protein powder sector for several reasons:

- Improved Freshness and Shelf Life: Robust multi – layer films protect protein powder from air, moisture, and light. They ensure longer – lasting freshness and efficacy.

- Cost – Efficient Packaging: Their flat, compact structure reduces material use and shipping costs. It still conveys sense of quality and care.

- Easy Portion Control: Single packets help consumers with portion management. They support on – the – go lifestyles.

- Eco – Friendly Possibilities: Advances on material science allow for recyclable or compostable 4 side seal sachets. They align with sustainability goals.

Vertical Form Fill Seal Machine vs. Premade Pouch Machine for 4 Side Seal Packaging

VFFS machines are best for high-speed, cost-effective, and highly flexible 4-side seal pouch production, especially for powders and granules.

Premade pouch machines are preferred for premium products with strict branding requirements, offering flexibility in custom pouch stocks.

For continuous, large-scale production with fast changeovers, VFFS is typically more efficient and economical.

| Feature | Vertical Form Fill Seal (VFFS) Machine | Premade Pouch (Rotary/Bag-Feeding) Machine |

|---|---|---|

| Packaging Process | Forms, fills, and seals pouches from rollstock vertically | Fills and seals pre-made 4-side seal pouches |

| Bag Type Flexibility | Versatile: easily adapts to 3-side, 4-side seal, stick, pillow bags, and more | Limited to pre-formed pouch styles and sizes |

| Speed & Output | High-speed, especially suitable for large batches and continuous production | Moderate speed, optimized for small to medium batches |

| Material Efficiency | Less packaging material waste; forms bags precisely according to need | Uses more material due to pre-formed pouches |

| Product Suitable | Ideal for powders, granules, and liquids; highly customizable portion sizes | Well-suited for solid, premium, or fragile products |

| Customization | Bag size and filling volume can be adjusted quickly via machine controls | Relies on inventory of pre-purchased pouch sizes |

| Ease of Changeover | Fast changeover between products and bag types; suitable for multi-format production | Changeover requires manual switching of pouch types |

| Footprint | Space-saving, compact vertical design | Generally larger due to rotary/linear operations |

| Automation Level | Highly automated, integrates with upstream and downstream processes | Automated filling and sealing but manual pouch loading in some cases |

| Presentation/Appearance | Consistent, uniform pouches; supports high-speed branding/printing inline | Premium look depends on quality of premade pouches |

| Cost | Lower per-bag cost for high-run production; higher initial investment possible | Higher per-bag cost due to pre-made pouch purchase |

| Ideal Application | Mass production for food, pharma, and chemical industries, especially for single-serve sachets | Premium, retail-oriented packaging with strong shelf impact |

Lintyco 4 – Side Seal Sachet Packing Machine

To harness these benefits, investing on right machinery is crucial. Lintyco 4 – side seal sachet packing machine is designed specifically for efficient and precise protein powder packaging.

Lintyco’s Competitive Advantages

- High – Speed Output: It is engineered for large – scale production. It supports multiple lanes for high – throughput needs.

- Precision Filling System: It delivers accurate dosing. It minimizes waste and ensures consistent product weight in every sachet.

- Smart Automation: It integrates seamlessly on auto cartoning lines. This ensures smooth, uninterrupted workflows.

- Hygienic Design: It meets strict food safety and GMP standards. It utilizes materials that ensure no contamination of your protein powder.

- Easy Customization: It supports various sachet sizes and branding options. This matches market needs.

Want to upgrade your packaging line? Learn more about Lintyco’s 4 – Side Seal Sachet Packing Machine on our product page!

Frequently Asked Questions: 4 Side Seal Sachet for Protein Powder Packaging

1. What are 4 side seal sachets and why are they suited for protein powder packaging?

4 side seal sachets are flexible pouches sealed on all four sides, offering robust protection against moisture and contamination. They are ideal for protein powder packaging because they ensure freshness, enable precise portion control, and provide a clean, professional appearance.

2. Can 4 side seal sachets be customized for different serving sizes and branding?

Yes. These sachets can be produced in a wide range of sizes—from single-serve portions to larger packs. They also support full-color printing and custom design elements, allowing your branding and product information to stand out on the shelf.

3. How does the Lintyco 4-side seal sachet packing machine improve the packaging process?

The Lintyco machine is engineered for efficiency and accuracy, featuring high-speed output, precise powder dosing, multi-lane production, and hygienic construction. This ensures consistent packaging quality, minimal product waste, and compliance with food safety standards.

4. Are 4 side seal sachets eco-friendly?

Many 4 side seal sachets can be made from recyclable or compostable materials, making them a competitive choice for brands with sustainability goals. The packaging’s flat design also reduces material usage and shipping costs.

5. What are the main advantages of using 4 side seal sachets for protein powders compared to other packaging types?

- Superior product protection and longer shelf life.

- Enhanced portion control and convenience for consumers.

- Customizable appearance for brand differentiation.

- Efficient storage, shipping, and retail display due to their flat shape.

- Seamless integration with advanced sachet packaging machines for large-scale production.

Conclusion

4 side seal sachets offer modern, reliable, and efficient packaging for protein powders. They meet both business and consumer needs for quality, safety, and convenience. If you look to elevate your protein powder packaging, consider partnering with Lintyco for industry – leading machinery and support.