Industrial metal detector

Features

1.operating system adopts highly human-oriented and intelligent design. It has self-learning function, metal detector can set and save 100 types

of product parameters.

2. The detector is made by COSO unique materials and manufacturing techniques, possessing high sensitivity, strong ability for anti-interference,

stable performance and a service life of more than 10 years.

3.OEM and ODM is available

Advantage of metal detector

1. The test sensitivity is high

We can achieve the highest sensitivity of Fe: 0.6mm. The sensitivity is best when we place the examination ball on the surface

The conveyor belt. The actual test sensitivity is determined by the production detected and the field work environment.

2. The customization options are wide

The metal detector can adapt to high temperature and low temperature working conditions. The same applies to the very poor working conditions

the excellent sensitivity performance.

3. Adjusting the examination parameters is convenient

Adjusting the examination parameters to the metal detector is convenient and directly visible, the uniformity and stability of the examination

Parameters are very good. For the same examination product, the examination parameter does not change over time.

4. The waterproof and dustproof performance is good

According to the order, it can meet the waterproofing requirements of IP-65.

We are here for you, contact us today!

Structure of industrial metal detector

The basic function of the metal detector is to detect whether there are metallic impurities in the non-metallic medium. The presence of metal contaminants has a direct impact on product quality or perhaps directly on the important safety of production equipment. If food contains metal contaminants, it could potentially pose an imminent threat to personal safety or health.

The metal detector includes 4 series: H, L, P, T. It is suitable for food, medicine, chemical industry, plastics, chemical fiber and mining and any kind of different application.

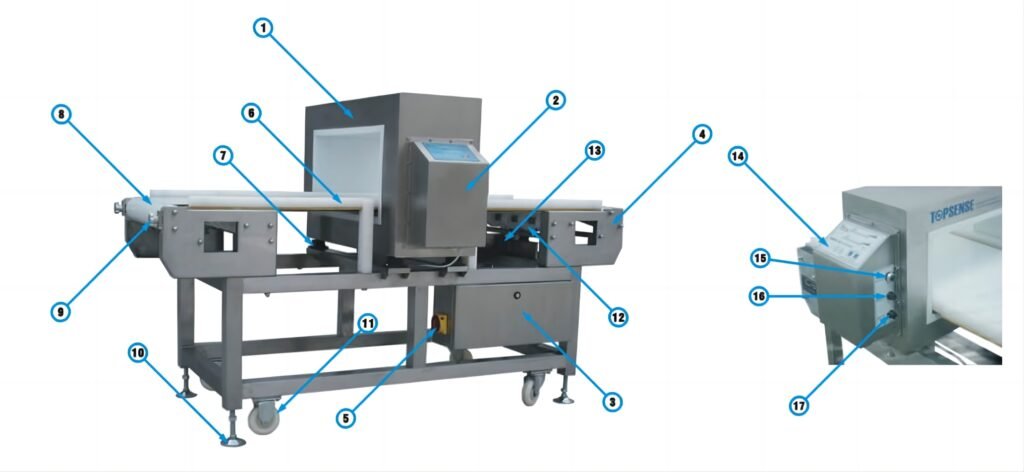

H series basic structure

1: Detector head

2: Instrument box

3: Power and control unit

4: Frame

5: Switch

6: Orientation pole

7.Shock absorber

8. the conveyor belt

9: Conveyor adjustment screw

10: Support

11: Wheel

12: Support wheel of the conveyor belt

13: Engine

14: Electrical panel

15: Product effect adjustment button

16: Channel 1 sensitivity adjustment knob

17: Channel 2 sensitivity adjustment knob

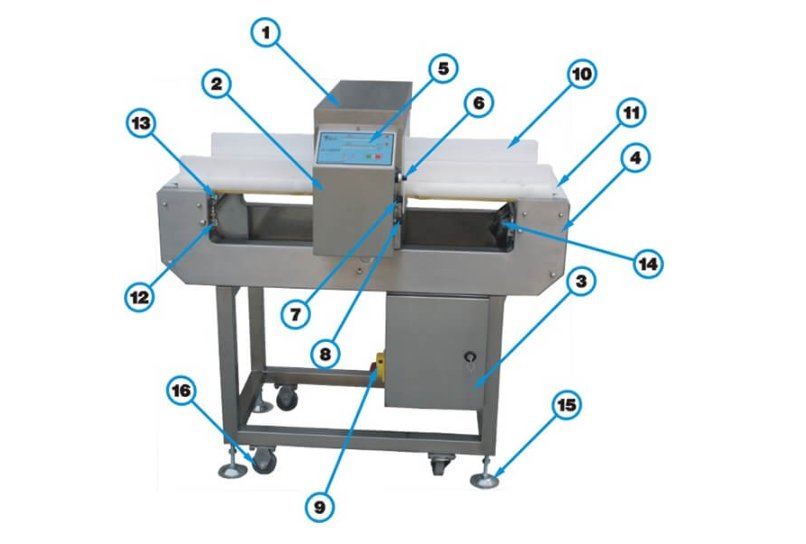

Basic structure of the L series

1: Detector head

2: Instrument box

3: Power and control box

4: Frame

5.the panel

6. Product effect adjustment knob

7.the sensitivity setting for channel 1

8: Channel 2 sensitivity adjustment knob

9.Switch

10: Orientation bar

11: Belt

12: Node

13: Conveyor belt adjustment knob

14.Engine

15.Support