Peeling machine for washing potatoes

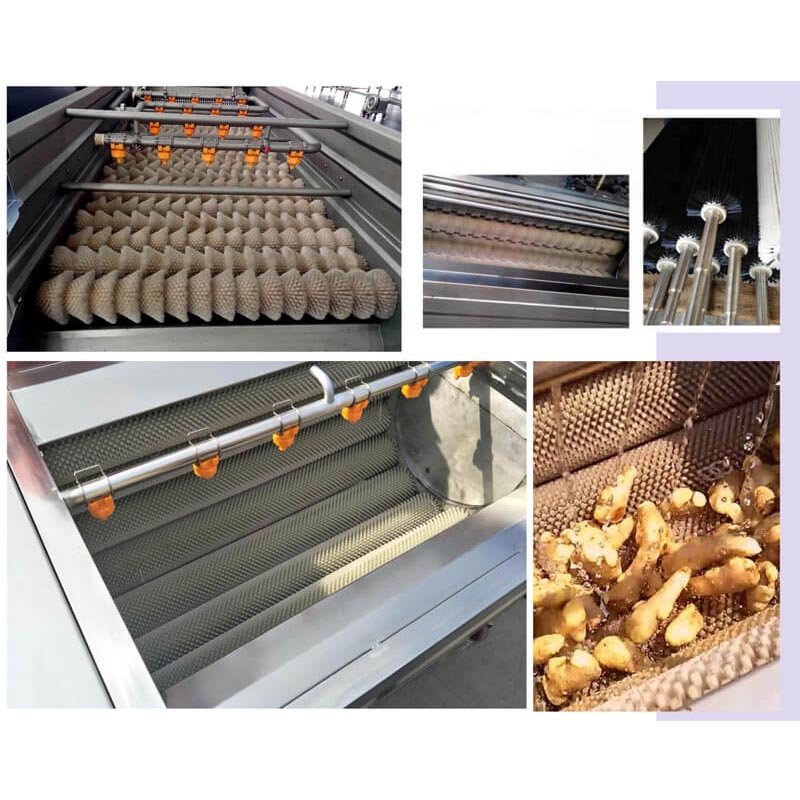

Using the brush friction principle, it is widely used for cleaning and peeling round, oval fruits and vegetables. The brush rollers are made of soft nylon material, which is durable. Other parts are made of stainless steel.

Features

1) The entire machine frame is made of stainless steel 304

2) Potato peeling machine combines cleaning, washing and peeling.

3) Large volume, high efficiency, steady work, low waste.

4) The potato peeling machine uses the brush principle with a peeling rate of over 98%

5) The cleaning process does not harm the fruits and vegetables, it could be used in vegetable cleaning industry.

6) The cleaning performance is good, the dust and agricultural chemicals could be cleaned thoroughly.

sample

It is suitable for root vegetables and fruits such as potatoes, sweet potatoes, radish, carrots, cassava, apples, kiwis, stems, sweet potatoes, ginger, radish, taro, rhizomes, areca seeds, betel nuts, etc.

The machine is suitable for potato chip production plants, vegetable processing plants, fruit processing plants, restaurants, etc.

We are here for you, contact us today!

Parameters of the peeling machine for washing potatoes

The brush cleaning peeling machine is mainly composed of a motor, a gearbox, a hair stick group, etc.

The whole machine is made of high quality stainless steel, rotating material, no rust, clean and hygienic.

Model | capacity | Performance | Weight | Dimensions (mm ) |

PB-800 | 800kg/h | 1.1kw/380V | 220kg | 1440*730*740 |

PB-1200 | 1200kg/h | 2.2kw/380V | 300kg | 2120*840*900 |

PB-1500 | 1500kg/h | 3kw/380V | 380kg | 2400*840*900 |

PB-1800 | 1800kg/h | 3kw/380V | 400kg | 2550*840*900 |

PB-2000 | 2000kg/h | 4kw/380V | 460kg | 2900*840*900 |

PB-3000 | 3000kg/h | 4kw/380V | 560kg | 2900*1100*900 |

PB-4000 | 4000kg/h | 4kw/380V | 600kg | 3050*1200*1160 |

PB-5000 | 5000kg/h | 5.5kw/380V | 700kg | 2900*1285*1150 |

frequently asked Questions

A potato washing peeling machine is a device used in food processing to efficiently clean and peel potatoes, often in large quantities, for industrial or commercial use.

The machine typically combines water spraying and mechanical action to clean the potatoes. Peeling is usually done by grinding rollers, brushes or blades that remove the peel as the potatoes rotate in the machine.

High efficiency: Can wash and peel large quantities of potatoes quickly.

Adjustable settings: User can control peeling thickness and washing intensity.

Durable materials: Usually made of stainless steel to ensure hygiene and durability.

Easy maintenance: Designed for quick cleaning and easy replacement of parts.

Most machines can handle different sizes and varieties of potatoes, from small to large and from soft-skinned to hard-skinned varieties.

Capacity varies depending on the model, but industrial machines typically process between 100 and 1000 kg of potatoes per hour.