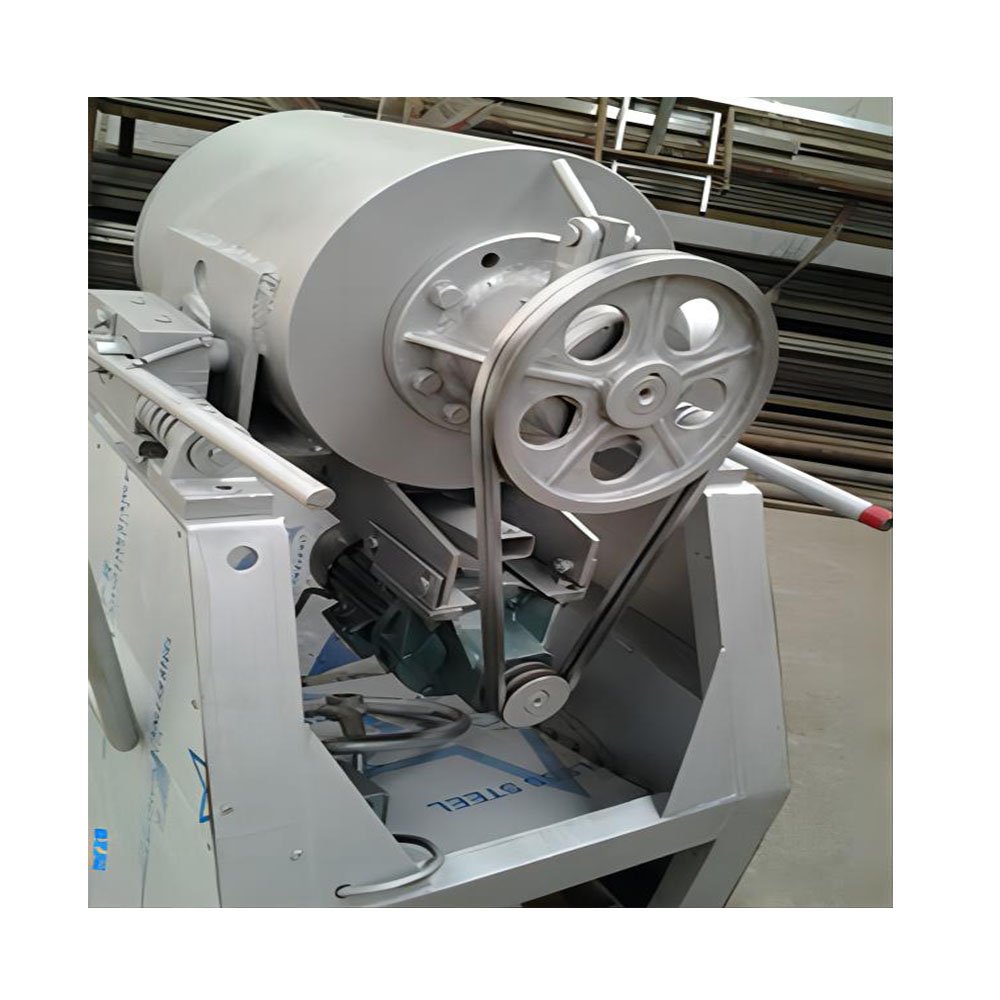

Airflow blowing machine

We offer a wide range of snack solutions, no matter how different your projects are, our professional perspective will provide you with the best solution.

Features

1. The large capacity of 60-90 kg/h.

2. High hygiene, free of lead in the puffing process.

3. The aroma and nutrients are perfectly preserved in the puffed foods.

4. Low energy consumption and high safety factors.

5. consistent work performance and product quality.

6. Simple design and easy operation.

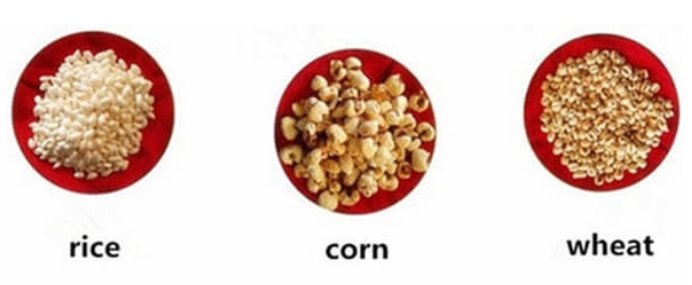

sample

We are here for you, contact us today!

Parameters of the airflow blowing machine

The airflow puffing machine can puff wheat, rice, millet, corn, buckwheat, wheat and other grains, perfectly preserving the original flavor and nutrients in the puffed products. The grain puffing machine adopts the advanced technology introduced from Japan and has the largest capacity in China. The iris is powered by liquefied gas or electricity. With its low energy consumption and high safety, the grain puffing machine has become one of the necessary equipment for puffed food manufacturers. Compared with the traditional puffing machine, it is more hygienic and can produce tastier food, which is more popular with consumers.

Model | AFP-330 |

capacity | 8-10KG |

Performance | 0.75KW |

dimension | 1650*800*1350 |

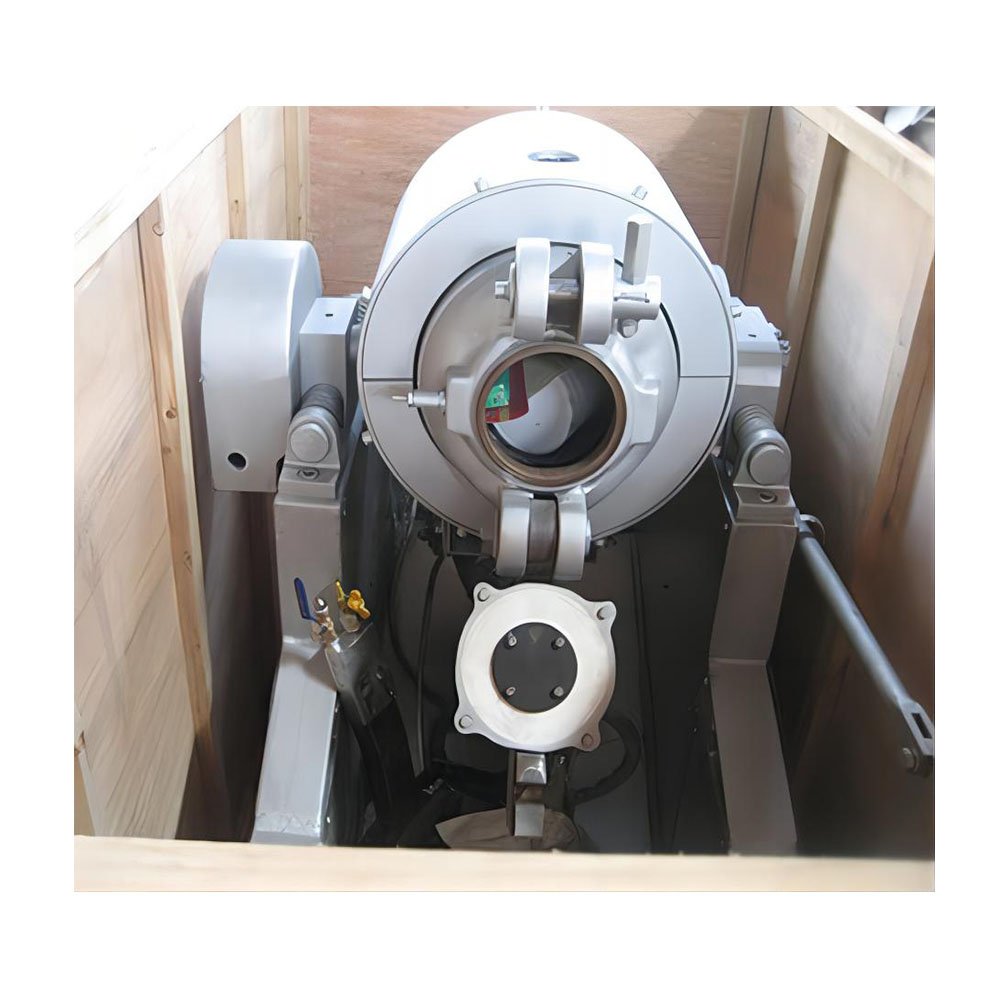

Attention for corn patty machine

1. If air leaks from the cap during normal production or the cap preloading does not work, replace the gasket with a new one.

2. If abnormal phenomenon of pressure gauge and thermometer occurs during normal production, stop the machine and check it immediately.

The machine can only be put back into operation when everything is working properly.

3. The pressure should never exceed 12 kg during operation!

4. The machine should be reliably grounded to avoid leakage current.

5. If a gas leak occurs in the LPG line, stop the machine and check it immediately. Close the main air supply valve after finishing work

completed.

FAQ

Corn puffing machines work by extruding the kernels through a high temperature and high pressure environment inside the machine, causing the kernels to puff up as they leave the extruder. The shape of the snacks can be customized by changing the molds or dies inside the machine.

A corn puffing machine can produce a variety of snack shapes, including hollow, crossed and solid balls, peanut shapes and more traditional shapes such as puffs and cheese balls. Products can be varied by adding flavors such as cheese or spices.

Yes, there are small corn puffing machines that are suitable for small scale production and enable businesses or individuals to produce puffed snacks efficiently on a smaller scale.

Corn puffing machines are equipment used to produce puffed corn snacks such as corn puffs and cheese balls. These machines use whole or crushed corn, rice or other grains as raw material to produce various snack shapes through an extrusion process.