Popcorn production line

We offer a wide range of popcorn processing solutions, no matter how different your projects are, our professional perspective will provide you with the best solution.

Features

1. Low power, high heating efficiency

2. Low operating costs, convenient to maintain

3. It can process the material evenly and stably, excellent product quality

4. High automation, labor saving.

sample

The popcorn processing machine is used for drying and popping popcorn, cornflakes, starch pellets, extruded snacks, vegetables and grains, as well as roasting nuts and coffee beans or pasteurizing ingredients.

We are here for you, contact us today!

Parameters of popcorn production line

As one of the most popular snacks all over the world, the popcorn is consumed more and more and our caramel popcorn production line can meet the huge demand for the popcorn. This line consists of 6 independent machines with a large capacity of 80-100kg/h. We can also add the independent machine to the line according to your other production requirements.

Model | LTC-100P |

capacity | 80~100kg/h |

Overall performance | 45KW |

Heating temperature | 0 ~ 300 °C |

dimension | 3700 * 1200 * 2000mm |

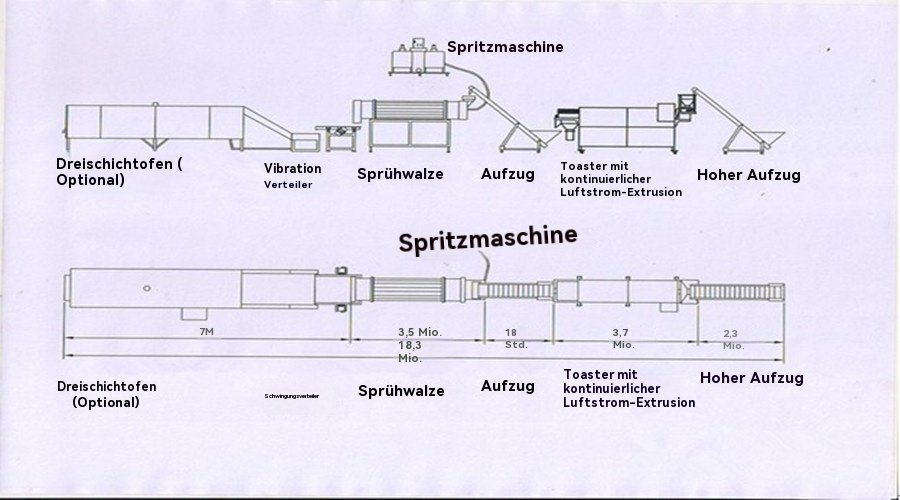

Popcorn machines in caramel popcorn production line

1. Popcorn making machine

The hot air popcorn popper – the main engine of the caramel popcorn production line is used to dry and pop the corn, it is equipped with a convincing ventilation heating system, an air flow baffle in the inner layer, precise temperature control and a sophisticated insulation layer, which makes it a compact and highly energy efficient process unit.

2. Elevator and conveyor belt (2 sets)

This machine is the auxiliary tool of this line to transport and lift the material to the next machine. It improves the automatic degree and saves labor.

3. Cooling and vibration distributor

After the corn is cut by rotary popcorn machine, it has high temperature. The vibrating distributor is used to cool the popcorn. The vibrating screen and outlet port are made of stainless steel to keep the production cleaner and the appearance more beautiful.

4. Roller and spray machine

Put the dried materials into the roller through the elevator, when the roller rotates, put the syrup into the spray machine and spray sugar into the surface of the food.

5. Electric oven

After the sugar is sprayed, the popcorn will automatically go into the oven to evaporate the water in the sugar. This device has many advantages, such as multi-purpose use and balance of heating system and so on.

Tips:When delivering machines, we can provide some related parts for free, such as elevator conveyor belt, relay, current meter and so on. The video is also available. For more information about the machines, please feel free to contact us.

frequently asked Questions

A popcorn production line is an automated system designed for the mass production of popcorn. It typically includes machines for popping corn, seasoning, packaging, and sometimes even adding toppings or flavorings.

Various varieties including traditional salted popcorn, butter popcorn, caramel popcorn, cheese popcorn and other flavored varieties.

The process typically involves feeding kernels into a popping machine, which uses heat (oil or air) to pop the kernels. The popcorn is then conveyed to a seasoning machine where flavors are added, and finally to packaging machines.

Air poppers use hot air to pop the kernels without oil, resulting in a healthier product. Oil poppers use heated oil, which can improve the flavor and texture of the popcorn.

Flavors are added using seasoning applicators that evenly distribute powders or liquids over the popcorn. Additional coating machines can be used for more complex coatings such as caramel or cheese.

Quality control is managed through regular inspections, automated monitoring systems and compliance with industry standards and safety regulations. Ensuring consistent raw material quality and proper machine calibration is also critical.