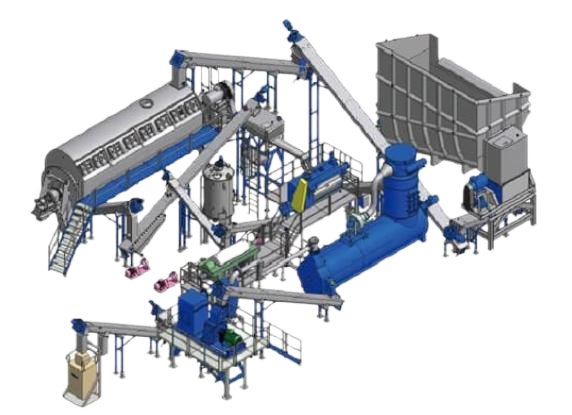

Fishmeal plant

Fishmeal factories are designed to meet the global need for sophisticated, reliable processing equipment that can be fitted into the very limited spaces below decks of trawlers and catcher processing machines.

Features

1. Widely used for pelletizing poultry, animals, pets and fish feed.

2. Food pellet size: 0.9-8mm, changed with different fish food shapes.

3. The screw made of special steel ensures high abrasion resistance and bearing force for the fish feed pellet machine.

4. Stainless steel conditioner keeps materials fully conditioned during pelleting of fish feed.

5. Food undergoes high temperature and pressure disinfection during pelleting.

6. Imported ED technology and components ensure long service life of fish feed pellet machine and competitive price.

sample

Fishmeal is a type of fish protein concentrate commonly used as an animal feed ingredient. We supply complete fish meal production plants for industrial use to produce high quality fish powder by processing the fish leftovers or whole fish with no economic value.

We are here for you, contact us today!

Fish meal production process

Raw materials – steaming – cooking – pressing – oil-water separation (HSH oil) – drying – crushing – cooling – fish meal

Fishmeal production line equipment

Fish cutting machine application: Cut large whole fish and fish heads into small pieces of 5cm in size to improve the efficiency of the curing process.

Features of the fish cutting machine

1.Single shaft structure; Pneumatic control of the cover lip for opening and closing.

2. The serrated cutter is made of wear-resistant alloy steel, and the cutter and anvil also undergo surface hardening treatment

permanently; The machine frame is made of Q235 carbon steel. The housing is made of 304 stainless steel.

3.Low noise, high efficiency; automatic cleaning; Compact structure to prevent environmental pollution.

Screw conveyor application

To transport the powdery, granular and lumpy etc. unsolidified materials to the designated position for the next process step.

Features of screw conveyor

1. Made of carbon or stainless steel; easy to set up and good leak protection.

2. Available for loading and unloading multiple spots.

3.Can be used with other suitable devices by connecting and fixing.

Screw conveyor parameters

Model | LTC-SC200 | LTC-SC250 | LTC-SC300 | LTC-SC400 |

diameter | 200 | 250 | 300 | 400 |

length | 5 M | 5 M | 5 M | 5 M |

capacity | 6T/H | 10T/H | 12T/H | 15T/H |

reduction gear | Cycloidal gear | Cycloidal gear | Cycloidal gear | Cycloidal gear |

Gear ratio | 17 | 17 | 17 | 17 |

Performance | 1.5kw | 2.2kw | 3kw | 4kw |

Application for steam cooking machines

Braise the raw material to harden; Can also be used to process animal blood, hazelnuts and entrails for curing, degreasing, calibrating and solidifying.

Functions of the steamer

1.Automatic control of loading to ensure even and continuous braising.

2. Complete the braising by filling the steam into the shell, main shaft and screw ribs to maintain a stable protein level.

3. Driven by electrodeless speed adjustable motor, regulating the rolling speed of the main axis to meet various processing needs

Different fish of different sizes and seasons.

4. The automatic drain system recycles the steam condensate to reduce energy consumption.

5. The sealing device at both ends of the main axis with automatic adjustment and compression prevents the steam boiler from leaking.

6. The steel base makes the installation changeable and flexible. The stainless steel covered heat protection cover and observation cover make it corrosion resistant and easy to maintain.

Steam cooking machine parameters

Model | Container diameter (mm) | Length of tank (mm) | Gas consumption (0.6MPa) | Production (t/h) | Engine power (kw) |

LTC-CM400 | 400 | 6000 | 250 | 1.5 | 2.2/3 |

LTC-CM500 | 500 | 6000 | 350 | 2 | 3/4 |

LTC-CM600 | 600 | 7000 | 500 | 3 | 4/5.5 |

LTC-CM700 | 700 | 8000 | 650 | 4 | 5.5/7.5 |

LTC-CM800 | 800 | 8000 | 750 | 5 | 7.5/11 |

Sewing machine application

To process the steamed fish for degreasing and dewatering to obtain press cakes, as well as the wet feathers, sterilized animal bones and meat, and kitchen waste

can also be pressed with this machine.

Features of the sewing machine

1. Screw press: Applicable to processing various high humidity materials for dewatering and animal materials for degreasing with high efficiency.

2. Different compression ratio: Designed according to different raw materials to achieve optimal moisture and fat removal.

3. The excitation speed control motor: regulate the rotation speed according to different materials to ensure the best pressing effect.

4. Double shaft presses: The two screws rotate against each other; The main axis can be designed as a single or double shaft depending on the output.

5. Tray-shaped basket base to collect the separated fat and water.

6. 45# steel, Q345 welded screw blades, stainless steel screen and outer cover, therefore corrosion resistant, abrasion resistant and durable.

7. Reasonable fully enclosed design, no leakage, low energy consumption and easy maintenance.

Press machine technical data

Model | Size of cylinder (mm) | Capacity (t/h) | Power kW) | reducer |

PM300 | 300*1600 | 1.5 | 15 | ZQ500 |

PM400 | 400*1800 | 2 | 18.5 | ZQ500 |

PM500 | 500*2000 | 3 | 22 | ZQ650 |

PM250-2 | 250-2*2600 | 3 | 18.5 | ZQ650 |

PM280-2 | 280-2*2600 | 4 | 22 | ZLY250 |

PM300-2 | 300-2*3000 | 6 | 30 | ZLY280 |

Application of oil-water separation machines

During the pressing process, oil and water are pressed. The machine separates oil and water to obtain fish oil through static sedimentation after the pressing process.

Features of oil water separator machine

1. Outer casing made of Q235B stainless steel, sturdy enough for long service life.

2. Equipped with a sight glass to observe oil-water separation; with the heating coil tube to prevent the oil from solidifying; with sockets for

Draining oil and waste.

Oil water separator machine specification

Model | Diameter (mm) | Height (mm) | Dimension (L) |

OSM1200 | 1200 | 2500 | 2000 |

OSM1400 | 1400 | 3500 | 4000 |

OSM1800 | 1800 | 4000 | 6000 |

Application for chain drive steam drying machines

It is a high efficiency, continuous operation conductive drying system used for drying press cakes.

Highlights of Chain Drive Steam Drying Machine

1. The drying process is completed by steam heating. The steam passes through the outer jacket and main axis tubes to expand the heating area, enabling highly efficient drying with low energy costs.

2. Equipped with a circuit board with self-cleaning function to advance the material to achieve better drying results; an automatic emptying system to recover the steam condensate to save energy costs and water.

3.Extractor hood and pipeline made of stainless steel, high corrosion resistance and long service life.

4. This drying system must be equipped with a boiler for generating steam. We also supply heat transfer oil system to facilitate drying. Completes the drying work by the heat generated by the oil heater after electrification. At the same time, the heat transfer oil system can provide heat for the cooking machine.

Chain drive steam drying machine parameters

Model | Tank size (mm) | Heat transfer area (m2) | Evaporation (kg/h) | Capacity (t/h) | Power kW) | reducer |

SDM1200 | 1200*6000 | 55 | 250-300 | 0.8 | 22 | Zly250/ZQ650 |

SDM1300 | 1300*7000 | 64 | 300-350 | 1.2 | 30/22 | ZLY280/ZQ650 |

SDM1400 | 1400*7000 | 81 | 350-400 | 1.4 | 11 | ZQ650 |

SDM1500 | 1500*7000 | 106 | 450-500 | 1.6 | 15 | ZQ650 |

SDM1600 | 1600*7000 | 120 | 550-650 | 2 | 22 | ZQ6560 |

SDM1800 | 1800*7000 | 146 | 700-800 | 2.5 | 22 | ZQ750 |

SDM2000 | 2000*7000 | 180 | 850-950 | 3.0 | 30 | ZQ750 |

Application of heat transfer oil system: It is an alternative to steam as a heating system for the entire fishmeal production plant. The heat transfer oil is heated after the system is electrified to supply the braising machine and the drying machine.

Application for shredding machines

The dried material is crushed to produce the powdery or granular end product.

Features of shredding machine

1.Multiple use: It is a kind of hammer mill equipment. In addition to the process of producing fish powder, it can also be used to crush agricultural materials, such as:

Branches, bark, corn stalks, peanut shells, dry grass, cotton stalks, etc., as well as medical materials and industrial materials such as Chinese medicines

stuff, quartz, coal, wood, etc.

2.High efficiency, reliable performance, simple structure, easy operation and maintenance.

Structure of the crushing machine: It consists of the feed hopper, rotor, sieve, feed feeding pipe, etc., and the feed storage container or bag can be equipped according to needs.

Working principle of shredding machine

1. The material enters the crushing chamber and is crushed by the impact of a high-speed rotating hammer.

2. Using the airflow, the shredded materials move along the outer edge of the rotor, exerting continuous friction against the hammer, tooth plate and screen. They are then pulverized.

3. Under the centrifugal force of the rotor and the suction force of the suction fan, the powdery final product is conveyed through the sieve into the storage container or bag.

Technical data of the shredding machine

Model | CMT360 | CMT400 | CMT500 |

Main axis rotation speed (min/n) | 4000 | 4000 | 4000 |

Rotor working diameter (mm) | 360 | 400 | 500 |

Hammer number | 16 | 16 | 24 |

Output (kg/h) | 150-250 | 250-500 | 500-700 |

Power kW) | 5.5-7.5 | 7.5-11 | 11-15 |

Application for drum cooling machines

For cooling the dried powdery or granular end product

Drum cooling machine performance

1.Rotary cooler: After the material enters the cooler, the material has full access to the air cooling medium under the action of the suction fan, and the countercurrent method is used for cooling.

2.Two-piece structure: The front part is for cooling and the back part is for shielding.

3. The end of the fan is connected to a dust remover.

4. Even and complete cooling result; stable operation; long lifetime.

Drum chiller parameters

Model | Diameter (mm) | Length (m) | Capacity (T/h) | Power kW) | Fan performance (m3/h) |

DCM1000-6 | 1000 | 6 | 1.5-2.0 | 2.2 | 5000 |

DCM1200-6 | 1200 | 6 | 2-3 | 3 | 6500 |

DCM1200-8 | 1200 | 8 | 3-5 | 4 | 7500 |

The electrical control cabinet controls the operation of the entire production line with reliable performance and has a front door to facilitate observation and maintenance.

FAQ

Fishmeal is made from small pelagic marine fish such as menhaden, herring, anchovies and sardines. The small fish are ground into a fine powder and the oil and water are then pressed out of the mixture. The resulting solids are cooked and further pulverized to produce a highly nutritious fish meal.

Fish meal is typically packaged in various types of containers to ensure its quality and prevent oxidation. Common packaging options include jute bags, multiwall paper bags with a polythene lining, and HDPE woven bags with a liner. This packaging helps protect the fish meal from exposure to air, as fish oils, being highly unsaturated, are prone to oxidation. By utilizing appropriate packaging materials, the fish meal remains safeguarded and maintains its nutritional value.

Fishmeal is a powdered substance obtained by cooking, pressing, drying and grinding fresh, raw fish. Fish oil, on the other hand, is a liquid obtained from cooked fish. Both fishmeal and fish oil are derived from the exploitation of short-lived, fast-growing populations of small, bony and oily fish that are not consumed on a large scale by humans. These fish species are specifically selected for their suitability for producing fishmeal and fish oil. Additionally, by taking advantage of these underutilized fish stocks, the fishing industry can maximize resource utilization and minimize waste.

Fishmeal is widely used in animal feed due to its impressive protein concentration. Additionally, it serves as a valuable source of essential minerals such as calcium, phosphorus and various other nutrients. Due to its high protein content and balanced amino acid profile, fishmeal is particularly popular in aquaculture feed and meets the nutritional needs of aquatic animals. Incorporating fishmeal into animal feed, particularly in aquaculture, helps support healthy growth, development and overall well-being of animals.