Paste grinding machine

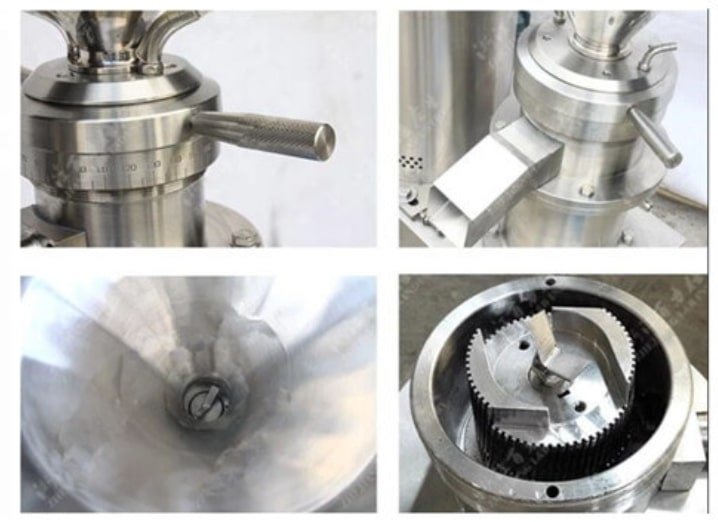

The paste grinding machine, also called colloid mill, is a newly developed device that introduces the latest technology. There are two types: one is made of semi-stainless steel with the main part made of stainless steel, and the other is made entirely of stainless steel.

Features

1. Made of semi-stainless steel or full stainless steel, clean and hygienic

2. Compact design, utility model and beautiful appearance

3. Good sealing, stable performance, easy to use and maintain

4. High automatic degree, high yield, good reliability

5. Widely used, high production efficiency and long service life

sample

Paste grinding machines are widely used in many industries as follows:

1. Food Industry: Dairy products, chocolate, bean paste, jam, peanut butter, cream drinks, etc.

2. Chemical Industry: Pigments, lubricants, spices, dyes, emulsified asphalt, emulsifying rubber,

Catalysts, paints, coatings, etc.

3. Pharmaceutical industry: cod liver oil, secrecy, athlete's paste, pollen, etc

4. Daily chemical industry: shoe polish, cosmetics, toothpaste, soap, detergent, balm, etc

5. Other industries: construction industry, paper industry, plastic industry, battery industry and so on

We are here for you, contact us today!

Parameters of paste grinding machine

Model | Capacity (kg) | fineness | Power kW) | Weight (kg) | Dimension (mm) |

PG-80 | 50-80 | 50-100 | 4 | 150 | 640*410*900 |

PG-110 | 100-200 | 100-200 | 7.5 | 175 | 700*430*980 |

PG-130 | 300-500 | 100-200 | 11 | 285 | 830*440*1100 |

PG-180 | 400-800 | 100-200 | 18.5 | 340 | 830*490*1100 |

PG-240 | 600-1000 | 100-200 | 37/45 | 1300 | 1320*500*1280 |

PG-300 | 600-1800 | 60-200 | 75/90 | 1600 | 1440*630*1420 |

Paste grinding machine working principle

Liquid or semi-liquid materials are crushed by the high-speed relative motion of rotor and stator, so that the material has strong shear force, friction force and high-frequency vibration, effectively crushing, emulsifying and homogenizing the material to obtain finely processed products.

The maintenance of the paste grinding machine

1. During the operation of the paste grinding machine, ensure that the storage temperature does not exceed the ambient temperature

The temperature is 35°C, the maximum temperature should not exceed 80°C.

2. If an unusual voice is heard during the working process, please stop immediately to check.

3. Check the wear of the axle sleeve regularly; please replace it in good time if there is greater wear

4. When the paste grinder is not used for a long time, you need to clean all parts of the pump and dry water, install rotating parts and combine layers with grease to properly preserve them.