Paddy separator

PSM series rice field separator is designed to separate paddy rice and pure brown rice from the mixture. It has strong adaptability to the variety of highly mixed materials. With high purity, high yield and stable performance, Chinese rice separator machine is the perfect processing equipment for rice mill plant.

Features

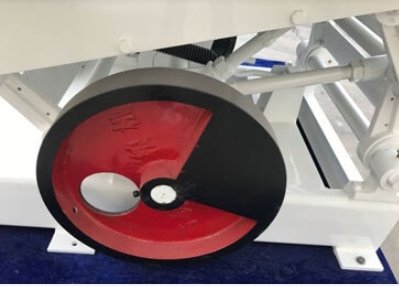

1. Reasonable structure, perfect process and easy operation.

2. Highly positioned strainer plate to reduce clogging

3. The reinforced gear structure ensures better mechanical performance

4. Unique speed controller and material separation device ensure more stable technological performance

5. Low mechanical center of gravity, good balance and reasonable rotation ensure reliable processing characteristics

sample

It is well suited for long and short grains and has stable processing properties. We can provide you with complete rice milling equipment.

We are here for you, contact us today!

Parameters of paddy separator

PSM series gravity rice separator machine is a professional rice separator machine for rice processing. It can significantly improve rice production and also increase profitability. It is a good choice for customers.

Please see the following technical parameters first and select the appropriate parameter according to your production capacity.

Model | capacity | Performance | Weight | dimension |

PSMX 80*5 | 1000kg/h | 0.75kw | 300kg | 1100*1120*1370mm |

PSMX 100*6 | 2000kg/h | 1.5kw | 450kg | 1600*1330*1560mm |

PSMX 100*8 | 2600kg/h | 1.5kw | 550kg | 1600*1330*1620mm |

PSMX 100*10 | 3000kg/h | 1.5kw | 650kg | 1600*1330*1660mm |

PSMX 100*12 | 3800kg/h | 1.5kw | 700kg | 1600*1330*1740mm |

PSMX 100*14 | 4500kg/h | 2.2kw | 750kg | 1460*1640*1600mm |

PSMX 100*16 | 5000kg/h | 2.2kw | 800kg | 1460*1700*1776mm |

Working process of rice separating machine

The rice separating machine adopts the different bulk densities of paddy rice and brown rice. By moving the sieves back and forth, the mixture of paddy rice and brown rice is automatically and gradually sorted. The heavy and small brown rice sinks, and through the transport function of the bidirectional inclined convex point separator plate, the brown rice is inclined to move upward over the drain of the separator plate; At the same time, the light and large paddy floating in the top of the brown rice tended to fall below the outlet of the separation plate, so as to achieve the result of separating the brown rice from the paddy.

FAQ

A paddy separator is a practical solution for efficiently separating brown rice from paddy. It accomplishes this by utilizing a reciprocating movement of the sieve plate, taking into account the varying bulk densities, specific gravities, and surface friction coefficients between the paddy and brown rice. This enables an effective separation process.

When a combination of paddy and rice descends onto a separator with a serrated surface and undergoes oscillation at the appropriate frequency, the rice settles beneath the layer of paddy. If the inclination of the deck exceeds the angle of friction between the rice and paddy, the paddy glides along the deck, resting atop the layer of rice.

Paddy separators function in an excellent manner, streamlining and facilitating the entire process. In rice mills, paddy rice is fed into the paddy separator. The separator efficiently separates the paddy rice from the brown rice, allowing for the subsequent removal of the separated paddy rice. Additionally, it is worth noting that paddy separators contribute to increased efficiency and productivity in rice milling operations.

The paddy separator effectively segregates unhusked paddy rice from brown rice. The quantity of paddy present is contingent upon the husker's efficiency and should not exceed 10%. Paddy separators operate by exploiting the variations in specific gravity, buoyancy, and size between paddy and brown rice. It is through these distinctions that the separation process is accomplished, ensuring the desired outcome. Additionally, it is important to note that paddy separators play a crucial role in optimizing the quality and yield of rice production.