Automated bagging has revolutionized product handling for modern industries. Where once laborious filling relied solely on human dexterity, advanced machinery now lends a lending robotic hand.

Pioneering automatic bag-filling systems streamlines operations across diverse sectors. Intelligent robots are fast, accurate, and reliable. They work in food, cosmetic, pharmaceutical, and chemical industries globally.

Compared to manual methods prone to fatigue and error, robot technicians work tirelessly and flawlessly. Integrated sensors, software and motors choreograph complex packing routines with unprecedented efficiency. Materials intake, controlled dosing, bagging and sealing unfold in perfect autonomous unison.

A brief review of packaging's past shows humble origins, but an ambitious evolutionary trajectory. Early prototypes hinted at the transformational potential of mechanical muscle. Today's robotic solutions surpass all expectations through state-of-the-art technologies.

Artificial intelligence and augmented capabilities foretell an even more capable future. Robots may soon intuit ideal settings for unknown tasks or seamlessly coordinate multi-step distribution systems. The possibilities are endless.

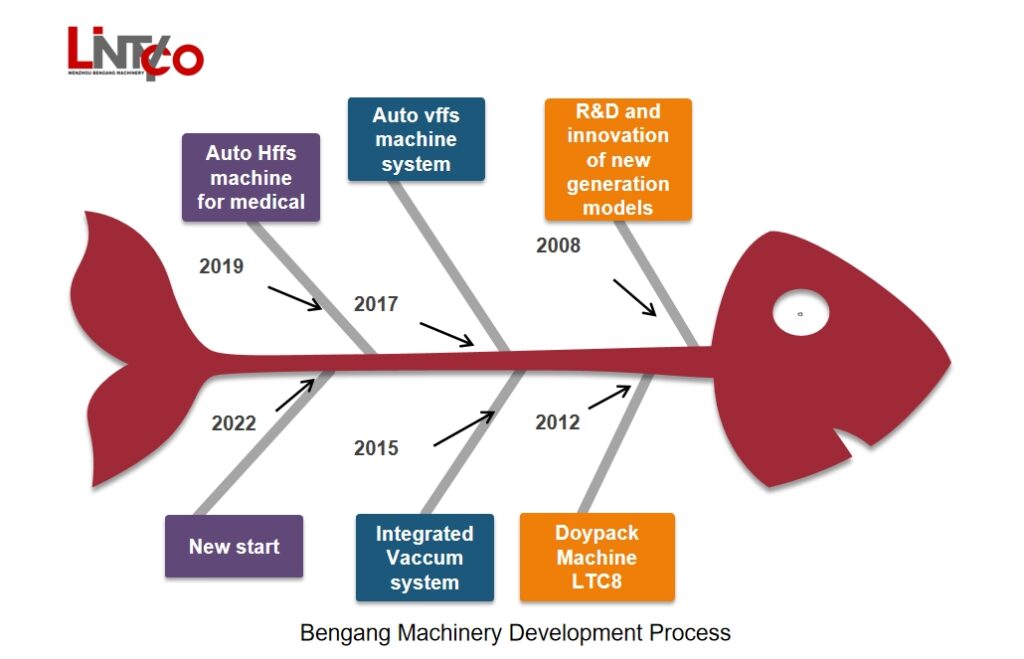

History of Automatic Bag Filling Machine

Industries first adopted automation during the Industrial Revolution, and the origins of automatic bag filling machines can be traced back to the late 19th century. This paved the way for higher productivity and consistent quality standards.

Early bagging machines were rudimentary mechanical designs, relying in part on manual input and gravity filling. While initial designs enabled semi-automated processes, human involvement exposed vulnerabilities that limited throughput and precision.

Technological advances expanded automation possibilities. Advances in electrical components improved measurement accuracy. Later, integrated computerization and robotics provided new versatility, making it possible to process different products and flexible bag sizes to meet market diversification.

Today's automated solutions bear little resemblance to the initial crude devices. Advanced electronics, software, motion controls and intelligent sensors enable completely independent operation. The configuration options cleverly adapt to any packaging requirement.

Continuous innovation also improves intelligence, connectivity and adaptability. Artificial intelligence and advanced technologies ensure even more adaptable, efficient solutions. The level of automation is increasing to optimize performance, quality and compliance in sectors such as food, pharmaceutical and consumer goods industries worldwide.

The automatic bag filler represents an evolutionary pinnacle, albeit a humble beginning, in the autonomous journey of packaging. Steady mechanical, electronic and digital advancements revolutionized what was once a manual task.

Types of bag filling machines

There are different types of bag filling machines on the market. Some common types are:

1.Gravity Driven Bag Filling Machines: These machines use gravity to fill bags with bulk materials. The materials flow from a funnel into the bags, driven by their own weight.

2.Auger fillers use a screw-like mechanism to move the material from a hopper into the bags. The screw ensures precise and controlled filling.

3.Valve Bag Filler: These machines are specially designed for filling valve bags that have a small opening with a valve. The valve enables easy and efficient filling of fine powders or granules.

4.Open-mouth bag fillers are machines that can fill bags with various materials such as granules, powders and small parts. They are often used in agriculture, the chemical industry and food processing.

5.Flow bag machines produce bags from film, fill them and seal them. They offer high-speed bag filling and packaging capabilities.

6.Bulk filling machines fill large bags, also called FIBCs or super bags. They are commonly used for handling and storing bulk materials such as grains, fertilizers and chemicals.

These are just a few examples of the bag filling machines available on the market. The choice of machine depends on factors such as the type of material to be filled, the bag size and type, the desired filling speed and the specific requirements of the industry.

Limitation of the bag filling machine

Although the automatic bag filling machine has certain advantages, it also has some limitations. For example, some irregularly shaped bags or small fragile or sticky items may cause difficulties requiring additional manual intervention. Care and maintenance also require a certain level of skill and experience. If the machine breaks down in the wrong way, the maintenance may take longer.

Of course, there are many types of packaging machines suitable for irregular materials as well as sticky and fragile materials. Choosing the right packaging machine, such as B. a bag packaging machine, solves part of the problem. Everything depends on the experience of the packaging machine factory and the level of engineers. Regarding maintenance, obse

How do you troubleshoot device problems?

Troubleshooting an automatic bag filling system

If problems occur, systematically check key systems and components:

Check Power Supply – Check proper electrical connections and power supply.

Check Mechanics – Check gears, belts and other moving parts for wear or damage. Replace if necessary.

Check sensors – Make sure the sensors for measurement and control are displayed correctly. Recalibrate or clean the sensors if they are faulty.

Check programming – Check the machine software parameters and interface for errors or irregularities.

Assess material flow – Monitor material movement and identify blockages or jams in the filling process. Remove obstacles.

Consult Manual – Refer to the manufacturer’s guidelines for your specific machine model for additional troubleshooting procedures.

If you approach these areas methodically, many problems can be solved. Pay attention to any abnormalities during inspections.

If problems persist after exhausting these options, contact the device manufacturer or an authorized technician. Their specialist knowledge of your system configuration optimizes further support in troubleshooting. Consider specialized maintenance if damage is discovered.

With a step-by-step approach, most malfunctions can be localized and efficiently resolved to restore production operations.

What should you consider when buying an automatic bag filling machine?

When selecting an automatic bag filling system, you should carefully consider several key criteria to find the right solution. Determine production needs and throughput requirements that match a machine's capacity. Versatility in terms of different bag types and materials ensures continuous use.

Precise dosage and control ensure consistency. User-friendly design simplifies operation and maintenance. Safety precautions protect operators.

The manufacturer's quality and reliability ensure lasting value. The total costs are weighed against the returns such as productivity and savings.

A careful evaluation of flexibility, accuracy, ease of use, safety features and financial elements results in a machine that positively impacts packaging throughput. Rely on proven manufacturers who offer replacement parts and long-term support. Comparing specifications to current and future goals results in a machine that is properly sized for nimble, efficient bag production today and tomorrow. With a well-researched selection, automation streamlines operations as intended.

Why you should trust Lintyco automated technology

As a leader in automation, Lintyco's pouch packaging systems offer state-of-the-art performance and reliability. Continuous innovation promotes the integration of new technologies and ensures optimized functionality.

Rigorous testing of high-grade components results in durable, long-lasting machinery. Customization options tailor solutions precisely to application and industry demands.

Decades of industry knowledge accumulated unparalleled expertise in automated bagging. Experts utilize insight to advantage clients throughout the process with personalized guidance and support.

Customer satisfaction ranks as the highest priority. Understanding requirements inspires tailored systems to achieve organizational goals and objectives.

Making a commitment to cutting-edge innovation, quality construction, customizable configurations and exceptional support Lintyco the leading provider of automatic packaging solutions. Your automated bag fillers streamline operations with optimized, reliable technology.