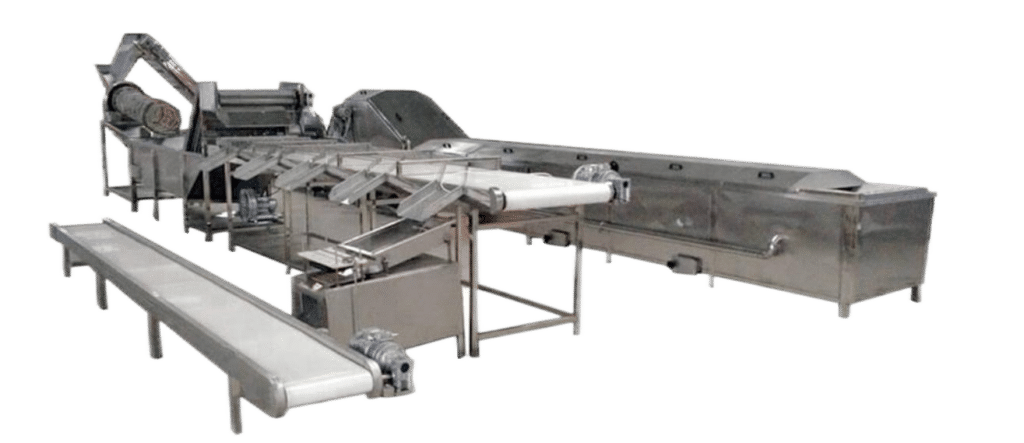

Process line for cooking and peeling quail eggs

All preheating and conveying of the quail eggs takes place in a large preheating tub where the quail eggs are soaked to prevent the eggs from breaking. A conveyor belt is installed in the preheating tank, which transports the quail eggs into the egg cooker.

Process line for cooking and peeling quail eggs

Preheat quail eggs——Cook quail eggs——-Cool quail eggs——-~ Peel and peel quail eggs

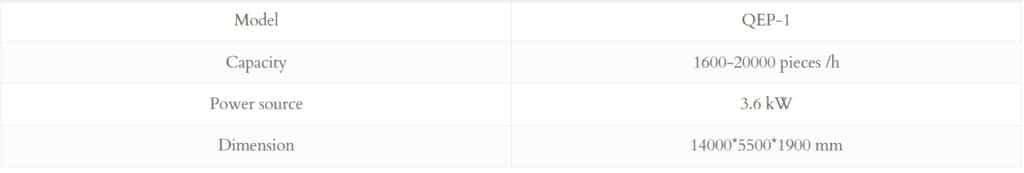

Cook quail eggs

After the quail eggs are sent to the egg cooker, the raw quail eggs turn into hard-boiled eggs. The egg cooker is the most important machine for the quail egg peeling system. The hard-boiled quail eggs are then automatically transported to the cooling tank.

Cryogenic cooling

After the quail eggs have passed through the cooling trough, the temperature drops and the shell of the quail eggs separates from the quail eggs, making the peeling process much easier.

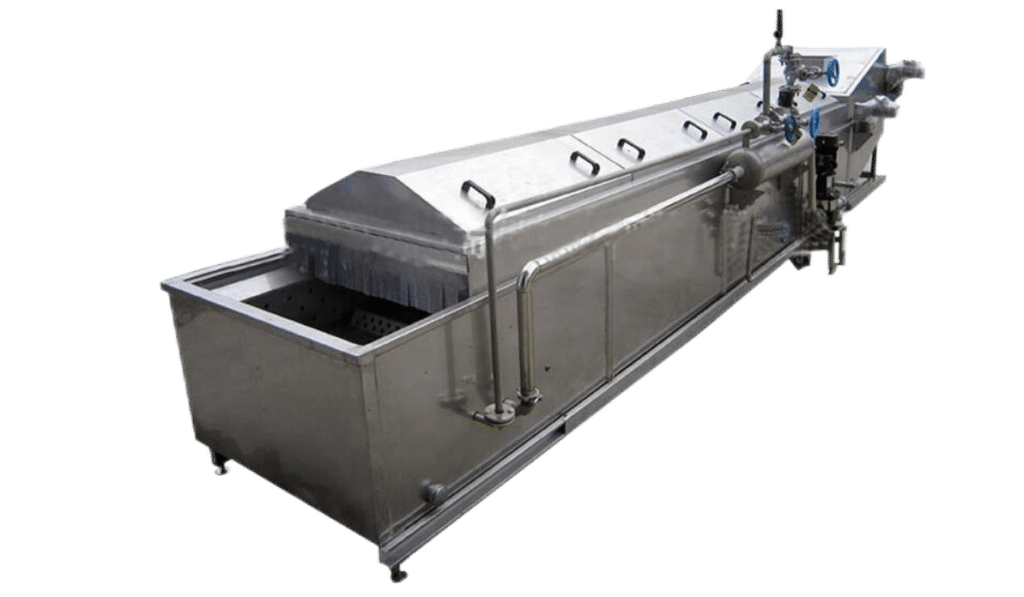

Breaking open the shells

The process of shell breaking is the most important preparatory work of shelling eggs, which is carried out by a rotary shell breaking machine.

The cracking machine can easily break the quail shells and will not cause any damage to the eggs. The structure of the machine is quite simple, so the machine is easy to operate and maintain.

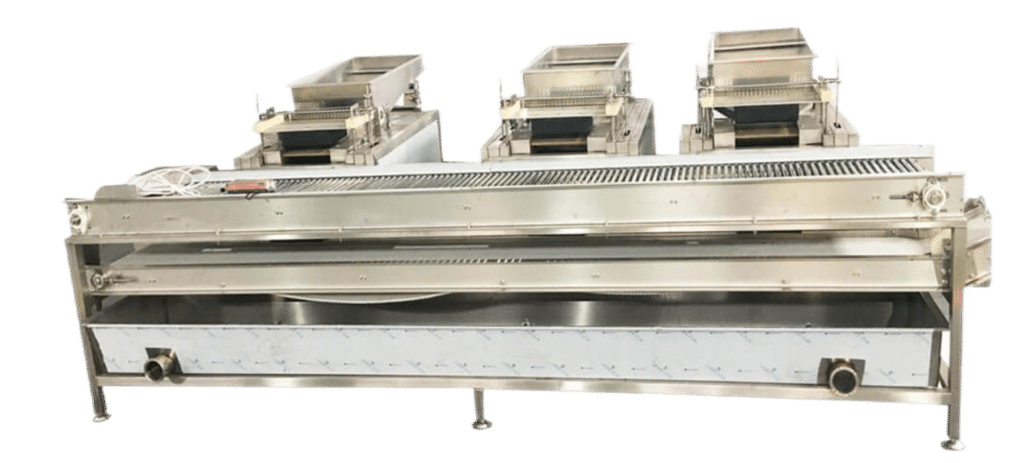

Peel quail eggs

Peeling quail eggs is the real goal of the entire production line. The production capacity of the machine is more than 10,000 pieces per hour and the breakage rate is less than 1%, which is a wonderful machine for any quail egg processing industry.

Transporting the peeled eggs

This is the last step of the entire quail egg processing line. A conveyor belt transports the peeled quail eggs into the prepared containers.

Why is Lintyco quail eggs peeling production line?

The quail egg shelling plant is a quail egg processing equipment, including cleaning, boiling the eggs, cracking the eggs and peeling the eggs, which can process the dirty and raw quail eggs quail eggs into clean, hard-boiled and shellless eggs. The corresponding machines are manufactured according to strict technological indicators and checked by the senior technicians. The entire peeling system is

labor-saving and efficient.