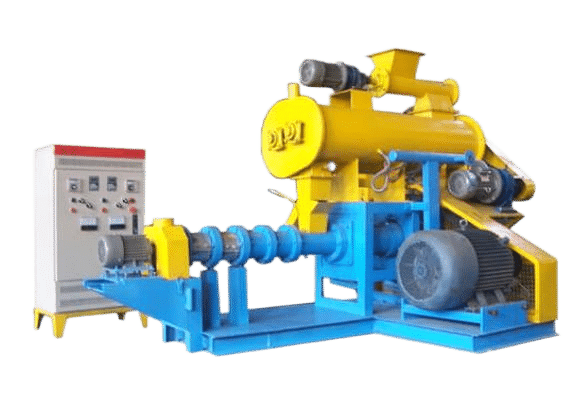

Pet food extruder

Also called wet food pellet extruder, this pet food extruder is equipped with a heating boiler that can continuously supply gas to fully cook the raw materials. of raw materials. The cooked material can be easily processed into high-quality feed pellets and is also more nutritious and easy to digest. Widely used for making fish food pellets, cat and dog food and other food pellets for various pets.

Features

1. The main extruder adopts frequency speed control, with high automation and stable performance.

2. The screws are made of alloy steel and are specially made, durable. Adopt the building block structure, compact and easy operation.

3. Forced lubrication system guarantees longer service life of feed pellet machine transmission system.

4. Through the automatic temperature control system, the temperature control is displayed more directly and the parameters are more precise.

5. The animal feed machine can be equipped with a heating boiler if necessary, which can be connected to the heating gas, which will fully cook the grains.

6. This pet feed extruder is widely used in producing feed pellets of various shapes for fish, dogs, cats, etc.

sample

Food extruders mainly process corn, soybeans and other grains into feed pellets for cats, dogs, rabbits, fish, shrimp, etc. Essential in the pet food industry.

We are here for you, contact us today!

Parameters of pet food machine

Model | Output (kg/h) | Main power (KW) |

FEM60 | 250-300 | 15 |

FEM70 | 350-450 | 18.5 |

FEM80 | 550-650 | 30 |

FEM90 | 750-900 | 37 |

FEM120 | 1100-1300 | 55 |

FEM135 | 1600-1800 | 75 |

FEM160 | 2200-2700 | 90 |

FEM200 | 3000-4000 | 132 |

FAQ

Extrusion cooking is the predominant method of producing pet food worldwide. Before the extrusion process, the ingredients are ground and mixed. Before the dry mixture enters the extruder barrel, a preconditioning stage takes place. In this phase, steam is used for heating and thorough mixing occurs, leaving enough time for hydration. This crucial step in the extrusion process ensures the optimal texture and quality of the final pet food product. Additionally, it helps improve the nutritional profile and digestibility of food.

When cooking dry pet food, commonly known as kibble, there are two main methods: extruding and baking. The majority of pet food available on the market is produced using the extrusion process. On the other hand, baking is a less commonly used method of preparing pet food. These two techniques offer distinct advantages and result in different textures and properties of the final product.

To initiate the cooking process, steam is introduced, while the preconditioned mixture (extrudate) is then conveyed through an extruder. The extruder consists of a solid, rotating screw that fits snugly into a stationary barrel and ends in the nozzle. The rotational movement of the extruder screw drives the extrudate through the system.

The composition of a comprehensive extrusion system varies depending on the products to be processed. Typically it includes storage containers, dry ingredient feeders, liquid pumps and meters, a preparation unit, an extrusion assembly, a molding device and a cutting mechanism. These components combine to form a complete extrusion system suitable for a variety of food processing applications.

There are two main categories of extruders: single screw and twin screw extruders, which include both co-rotating and counter-rotating configurations. These extruder types have a diverse selection of screw sizes (diameters), lengths and designs.