Compound potato chips frying plant

We offer a wide range of solutions for composite potato chips processing, no matter how different your projects are, our professional perspective will provide you with the best solution.

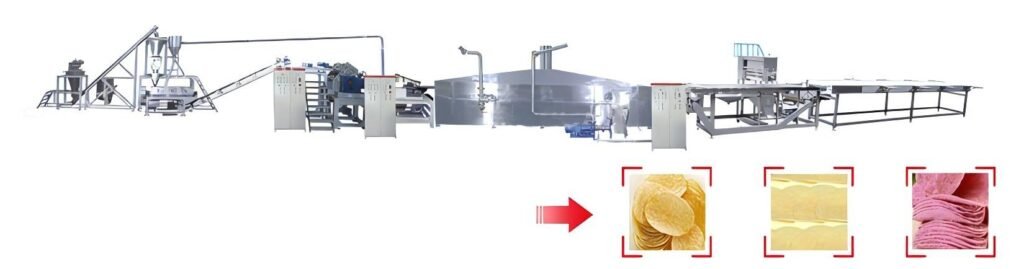

Automatic line for composite potato chips

The automatic compound potato chips line is designed to produce potato chips by using potato powder or potato flour as raw material. The main advantage of the compound potato chips line is the high efficiency of raw material utilization due to the recycling system, which can recycle and reuse the dough scraps. The finished compound potato chips have uniform shape and rich flavor, and can be packed in paper tubes or small bags. At present, the most popular compound potato chips are Pringles and Lays.

Features

1. Fully automatic PLC control system, all controls adopt international well-known brands, high precision and reliability.

2. Labor saving.The whole line is highly automated, only 8 – 10 workers are needed to operate it.

3. Provide the whole factory planning, human resource planning, product material analysis and technological formulation.

4. Many different flavors can be made by spraying powder with different flavor, such as tomato flavor, seaweed flavor, spicy flavor and so on.

5. The standard capacity of this automatic compound potato chips line is 250kg/h, but we can customize the complete production line according to your needs.

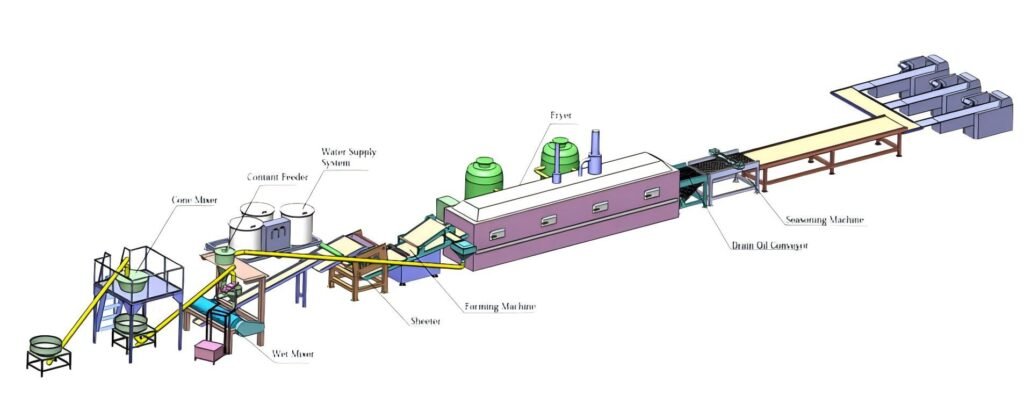

process

Mixing→Lifting→Dosing→Mixing→Lifting and distributing→Filming→Forming→Oil frying→Oil filtering→Spraying seasoning→Cooling and collecting→Packing

We are here for you, contact us today!

Parameters of Compound Potato Chips Frying Line

The automatic potato chips production line consists of the following important parts.

Dry mixing machine

The dry mixing machine is one of the important equipment in the automatic compound potato chips plant. It is used to mix the raw material.

| dry mixer | |

| dimension | 1080*1140*2350mm |

| Performance | 2.6 KWH |

| Weight | 680KG |

| machine material | Full 304 stainless steel |

| Tension | 380V/50HZ |

| capacity | 250 kg/hr |

Wet mixer

The wet mixer is one of the most important equipments of the complex potato chips production line. It can be used to mix the potato powder with water and prepare it for rolling.

| Wet mixer | |

| dimension | 2220mm*1390mm*1220mm |

| Performance | 11.75 KWH |

| Weight | 1600KG |

| machine material | Full 304 stainless steel |

| Tension | 380V/50HZ |

| capacity | 250kg/hour |

Stirring mixer

An agitator mixer is used to mix raw materials by stirring.

| capacity | 200-250 kg/hr |

| Performance | 12.5 kw |

| dimension | 2300*1460*3280 mm |

| Weight | 1600 kg |

Cross cutting machine

The dough sheeter can distribute the wet potato powder into the dough sheet with the required thickness. Advanced technology of double roller design for good dough sheeting effect.

Cross cutting machine

| dimension | 3300mm*1500mm*2450 mm |

| Performance | 19.25 KWH |

| Weight | 7000KG |

| Frame | U-steel |

| type of film | Twin roller |

| Sheeting roller | double roller |

| rolling roller solid roller | SKF |

| Tension | 380V/50HZ |

| capacity | 250kg/hour |

Forming machine

The forming machine can be used to form the shape of the chips.

| Forming machine | |

| dimension | 3380*1560*2000 mm |

| Performance | 4.5 Kw |

| Weight | 1200KG |

| Frame | stainless steel |

| drive roller | stainless steel |

| auxiliary role | stainless steel |

| forming roller | stainless steel |

| promote | PU |

| Tension | 380V/50HZ |

| capacity | 250kg/hour |

Disintegrator system

A disintegrator system is used to recycle the remaining material.

| Disintegrator system | |

| dimension | 1560*1160*2050 mm |

| Performance | 8.6 KWH |

| Weight | 680KG |

| machine material | Full 304 stainless steel |

| Tension | 380V/50HZ |

| capacity | 250kg/hour |

Deep fryer

The deep fryer can be used to fry the French fries and bring the assembled chips into a solid shape.

| dimension | 9100*1800*2430 mm |

| Performance | 30 KWH |

| Weight | 6000KG |

| Frame | U-steel |

| frying tunnel | stainless steel |

| cover | stainless steel |

| transfer belt | stainless steel |

| fastening system for chips | stainless steel |

| chip removal system | stainless steel |

| Roasting hood raises and lowers | Automatic screw lifter |

| base oil filter | Including |

| oil tank | Including |

| oil recycling pipeline | Including |

| capacity | 250 kg/hr |

Aroma system with conveyor belt

A flavoring machine with a conveyor belt can be used to flavor the chips with different flavorings. It is a seasoning machine with good effect for spraying different flavor powders.

| dimension | 4300*2200*1800 mm |

| Performance | 3 KWH |

| Weight | 900KG |

| machine material | Full 304 stainless steel |

| capacity | 250 kg/hr |

| Tension | 380V/50HZ |

Conveyor belt for food

The conveyor belt is used to convey the finished potato chips to the packaging line. With a PLC system inside, the operator can choose between automatic or manual control.

| capacity | 200-250 kg/hr |

| Performance | 1.5 kw |

| dimension | 8000*1150*1100 mm |

| Weight | 960 kg |

frequently asked Questions

An automatic compound potato chips production line is a fully automated system designed to produce potato chips from potato flakes or potato starch. The process includes mixing, forming, frying, seasoning and packaging, with all steps controlled by a series of machines in a continuous flow.

- Mixer: Combines potato flakes/starch with water and other ingredients to create a dough.

- Dough conveyor: Transports the dough to the forming machine.

- Forming machine: Form the dough into thin slices.

- Deep fryer: Fry the potato slices at a controlled temperature to achieve the desired crispiness.

- Seasoning machine: Adds flavors and spices to the fried chips.

- Cooling conveyor: Cool the chips before packaging.

- Packaging machine: Packs the chips into bags ready for distribution.

Production lines vary in capacity depending on design and size. Capacities can range from 100 kg/hour to over 1000 kg/hour. The exact capacity will depend on the specifications of the line you choose.

The production line is mainly used to produce compound potato chips which are made from potato flakes or starch. These chips can be flavored and shaped in various ways to meet market demands.

Yes, production lines can be customized based on the manufacturer's specific needs, including adjustments in capacity, chip thickness, frying time, seasoning types and packaging requirements.

Power requirements vary depending on the size and capacity of the line. Typically, these lines require a 3-phase power supply and the total power consumption can range from 100 kW to 500 kW.

Setting up the production line can take from a few weeks to several months, depending on the complexity of the system and the availability of components. Installation, testing and training of personnel are included in this time frame.

Regular maintenance is necessary to keep the production line running efficiently. This includes cleaning, lubrication and routine checks of all mechanical and electrical components. Maintenance schedules can be adapted to the intensity of use and environmental conditions.

Yes, the production line can be customized to produce different flavors and shapes. This typically requires changes in the seasoning machine and adjustments to the forming machine to create different shapes of chips.

Delivery time is typically between 3 and 6 months, depending on the complexity of the production line and the manufacturer's schedule.

Most manufacturers offer after-sales support, including remote assistance, spare parts supply and on-site training for operators. It is recommended to clarify these details with the supplier before purchasing

The primary raw materials include potato flakes or potato starch, water, oil for frying and various spices or flavorings. High-quality raw materials are crucial for producing premium potato chips.

With proper maintenance, an automatic compound potato chips production line can last 10-15 years or more. The service life depends on the intensity of use, maintenance practices and the quality of the machines.

Yes, in many cases the production line can be integrated into existing equipment, such as packaging machines or conveyor belts. However, this requires careful planning and possible adjustments to ensure compatibility.

Depending on your country or region, you may need special permits or certifications related to food production, hygiene and safety standards. It is important to check local regulations before setting up the production line.

The production line is equipped with various safety features such as emergency stop switches, safety covers and automatic shutdown systems in case of malfunction. Regular safety checks and employee training are recommended to ensure a safe working environment.

The production line is designed to produce high-quality, uniform potato chips with consistent texture and taste. Quality assurance systems can be integrated to monitor parameters such as chip thickness, oil content and seasoning level.