Potato chips baking line

We offer a wide range of solutions for potato chips production, no matter how different your projects are, our professional perspective will provide you with the best solution.

Features

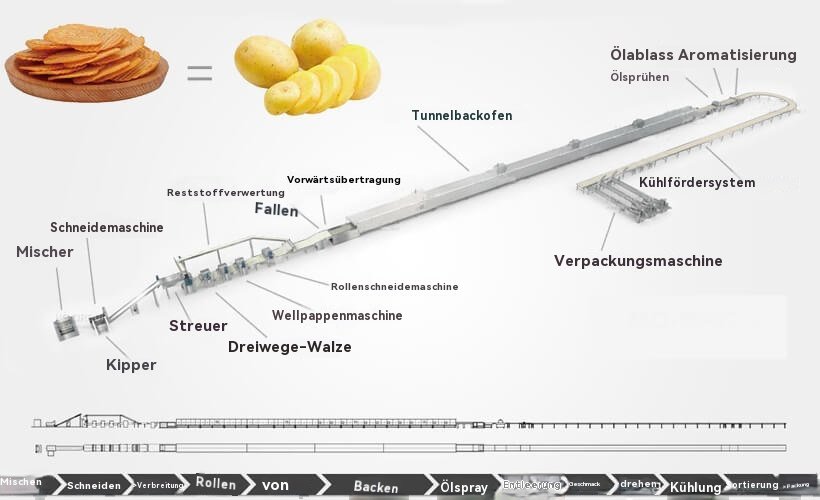

The baked potato chips production line is developed on the basis of the oil-fried potato chips processing plant. This chips processing line features high automation, easy operation and smooth running, and is suitable for the industrial production of non-fried potato chips. The main processing steps are rolling, baking and flavoring.

The potato chips are baked in tunnel oven rather than fried in deep fryer and then seasoned. Chips of different flavors can be made by spraying different flavored powders, such as tomato flavor, seaweed flavor, spicy flavor and so on. Baked potato chips are healthy and popular all over the world.

process

Lifting→Mixing→Constant Conveyor Belt→Distributing→Continuous Rolling→Sheet→Forming→Baking→Oil Spraying→Seasoning→Cooling→Sorting→Packaging

We are here for you, contact us today!

Parameters of the potato chips baking line

The main processing machines for baked potato chips are potato powder mixing machines, sheeting machines, potato chips forming machines, residue recycling machines, oil spraying machines, tunnel chip baking ovens, cooling conveyor systems, seasonal spraying machines and packaging machines.

Model | LPC250 | PLD-LPC500 |

capacity | 250kg/h | 500kg/h |

Performance | 130 kw/h | 140kw/h |

Gas consumption | 25kg/h | 45-50kg/h |

Compressed air pressure | 25-30 m³/h | 35-40 m³/h |

length | 30m | 40m |

Thickness of chips | 1-5mm | 1-5mm |

frequently asked Questions

An automatic baked potato chips production line is a fully automated system for producing baked potato chips from raw potatoes. The production line includes several stages such as washing, peeling, cutting, baking, seasoning and packaging.

The main components usually include:

Washing and peeling machine for potatoes

Potato cutting machine

Conveyor belt system

oven

Seasoning machine

Cooling system

Packaging machine

Production capacity can vary depending on the configuration of the line. Common capacities range from 100 kg/h to 1000 kg/h or more. Custom configurations are available to meet different production requirements.

The production line can process various potato varieties, including Russet, Yukon Gold and red potatoes. It is important that the potatoes are of good quality and free from significant defects.

After cutting, the potato slices are evenly distributed on a conveyor belt that passes through an oven. The oven uses controlled heat to cook the fries to the desired level of crispiness without the need for frying.

Baked chips are generally considered healthier than fried chips because they contain less oil and fat. They also have a lower calorie count and are often perceived as a healthier snack option.

a, The seasoning machine in the production line can apply a variety of flavors to the chips, such as cheese, barbecue, sour cream and onion and more.

Regular maintenance includes checking mechanical parts for wear, lubricating moving parts, and ensuring the oven is functioning properly. Cleaning includes removing potato residue from machinery, disinfecting surfaces, and following food safety guidelines.