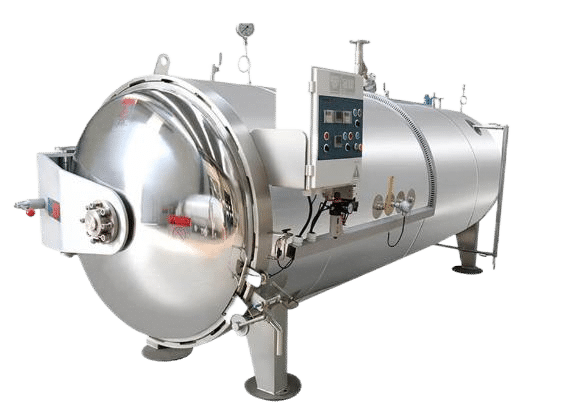

Steam retort

This steam retort is widely used to sterilize plastic bags, plastic or glass bottle packaging, can packaging, jars, bags, pet bottles, etc. The food sterilization machine kills microorganisms quickly without the use of toxic chemicals.

Features

1. Equipped with pressure cage and safety valve, reliable working process.

2. Low noise; hygiene sterilizer environment; Chemical-free sterilization process.

3. Four temperature sensor detectors installed in the livestock to monitor heat distribution at any time.

4. Optimal pressure control for minimal deformability of product packaging.

sample

Steam air retort enables thermal processing of a numerous variety of containers involving glass, metal cans, rigid plastic, and flexible pouches.

We are here for you, contact us today!

Steam retort parameters

Model | SRA900 |

capacity | 100 glasses |

Performance | 2kW |

Dimensions | 3500*1600*1450mm |

Steam-air retort structure

The steam retort machine is composed of casing, cover, starting system, locking system, safe locking device, rail, baskets, steam pipe and other pipes.

The cover is sealed by inflatable silicone rings, which are reliable and durable. The steam and the atomized sterilization water are mixed in it

Food autoclave, this reduces steam consumption and allows the temperature to change quickly.

FAQ

The retort process functions by effectively “cooking” packaged food. This process involves placing the food into a pouch or another suitable format, sealing it, and subjecting it to elevated temperatures to accomplish the desired outcome. The heating stage reaches extremely high temperatures to ensure proper cooking and preservation of the food.

The Innovaster Direct Steam Retort is used to process rigid containers such as cans. The retort chamber should be initially saturated as air is considered an insulating medium and all air is evacuated from the retort by flooding the container with steam and allowing the air to escape through vent valves.

Steam is injected directly into the bottom of the retort for a quick and even rise. Water jets running along the entire length of the jacket mix the steam and water intensively and ensure a homogeneous temperature distribution, which leads to a uniform process throughout the entire retort.